When working with acrylic, it’s very important to make precise cuts. Sharp and smooth edges make any product look better and safer. The first step to making good acrylic work is to cut it correctly. Professional acrylic cutters often make lines that are straight and edges that are straight. That way, each piece can keep its original shape. This method can help homes, businesses, schools, and factories.

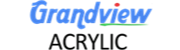

The sizes of each cut are just right. Each finished piece goes to its right place without any trouble or damage. A good acrylic cutting company has a lot of experience and is patient. It uses the latest machines and skilled workers. It looks like acrylic is strong, shiny, and clean. Both big panels and small parts get the same amount of attention. Precision cutting makes every product more beautiful and long-lasting. It also makes acrylic last longer, which is a nice bonus.

Crucial Side of Clean Acrylic Edges

Clean edges are very important for safety. When edges are smooth, there is less of a chance of cuts and cracks. They also make things made of acrylic look better in general. Rough edges could be the reason for wear and tear on the sheet. When put under stress, they might crack or chip. When the edges are kept clean, acrylic stays stable and accurate for a long time.

Acrylic Cutting well can help you save time and money. Less material is wasted. The costs of repairs and replacements go down. If the edges are clean, you don’t need to polish them again. Because of this, many brands and construction companies choose to hire professionals to cut acrylic.

Modern Methods Used in Acrylic Cutting

There are a number of modern ways to cut acrylic sheets. Different methods can give you different results. The best way to do it depends on the size, thickness, and design needs. Cutting by hand in the past didn’t make things as good as modern cutting methods do.

- CNC cutting of acrylic makes it possible to get exact and clean shapes.

- Making smooth, shiny surfaces with an acrylic cutting laser

- Tools for small and simple jobs

- Steps for polishing to get very sharp edges

Pick the right way to get the best result. It keeps the acrylic from breaking when you cut it.

CNC Technology for Perfect Accuracy

A computer numerical control (CNC) machine uses CAD files to cut acrylic. It follows exact lines and dimensions. When cutting, the machine runs at a steady speed and is very easy to control. No cut goes against the plan. There are no mistakes or rough edges.

This cutting method works best on signs, panels, boards, and custom parts. It might be able to hold complex shapes and patterns that repeat. For complex cutting designs that require exact precision time and time again, CNC cutting is the way to go.

Laser Cutting for Fine Detail Work

Laser cutting uses heat and focused light. It cuts acrylic without touching it. This helps keep the edges clean and smooth. The acrylic cutting laser works best when cutting thin sheets or complicated shapes. Branding, name plates, display items, and lettering are all common uses. The edges of the finished product are smooth and shiny. Most of the time, there is no need for extra finishing after the cutting is done.

Acrylic Cutting Speed and Quality Balance

The right acrylic cutting speed is a crucial component of quality. If you cut too quickly, the edges could melt or bend. A delayed process could cause burns on the surface. Professional operators change the speed based on the type, color, and thickness of the sheet. This careful management keeps the edges clean and free of clutter. Also, it keeps the acrylic from getting damaged by heat.

Tools Used in Professional Acrylic Cutting

You need good tools to get better results. Modern technology and sharp tools need people who know how to use them. Each tool has a specific job to do when cutting.

- Sharp acrylic-cutting tools for clean lines

- CNC routers for strong and accurate cuts

- Laser machines for fine detail work

- Polishing wheels for smooth finishes

Applications of Acrylic Cutting in Daily Life

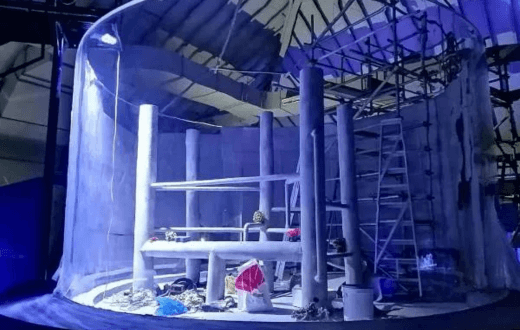

Acrylic-cutting has many uses in everyday life. Acrylic is a great material because it is light, strong, and see-through. Because of this, it is useful in many areas.

- Signboards and nameplates

- Kitchen and food items

- Shop and store displays

- Furniture panels and covers

- Safety guards and shields

From small homes to large factories, acrylic products are used everywhere.

Recommended Acrylic Cutting Products

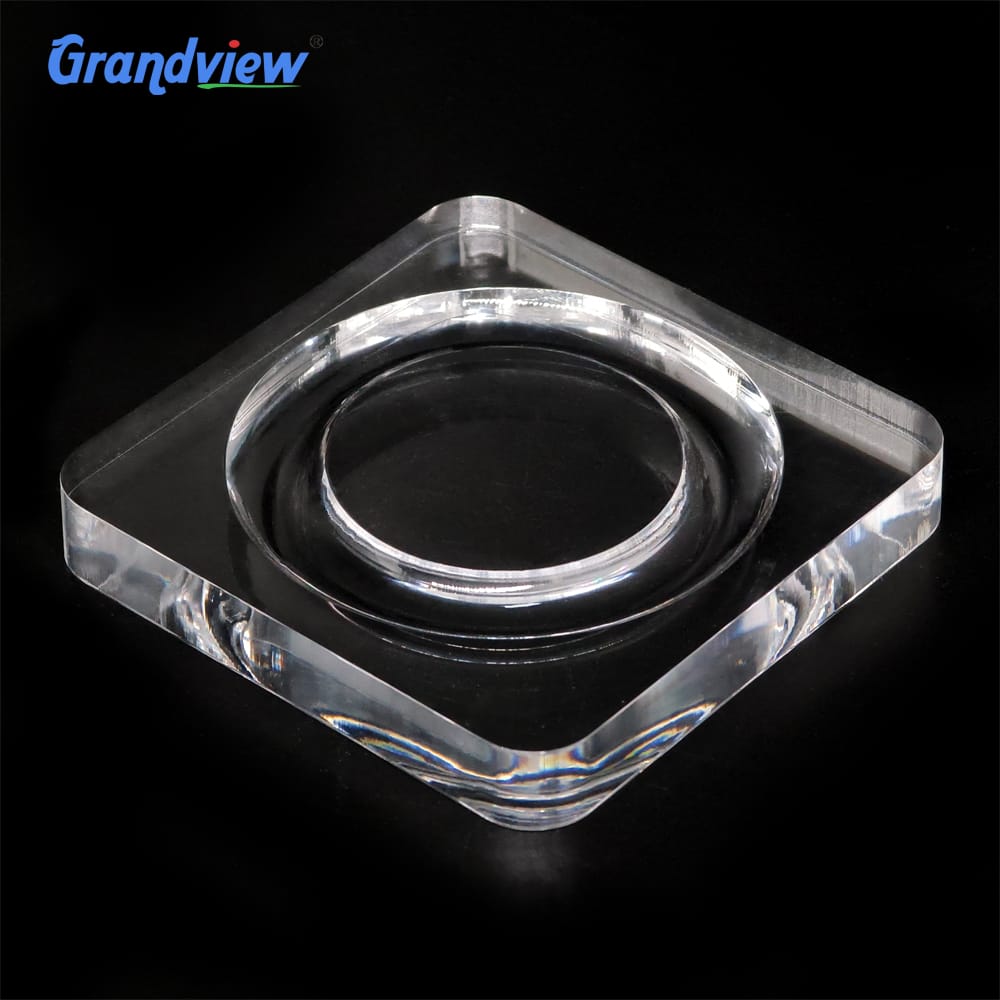

Customize Clear Bending Chunky Plexiglass PMMA Plastic Sheets

These thick, strong acrylic sheets are see-through. When bent, they won’t break. They are sharp and easy to cut through. With UV printing support, you can now design in more ways. You can save time and effort with the cut-to-size service. For the best results, use these sheets with your displays, furniture, and panels. These are the best materials to use when durability and visibility are most important, like when making a custom cutting board.

100% Acrylic Solid Surface Cutting Board Perspex Sheet

This 100% Acrylic Solid Sheet is safe to use around food and will last a long time. It stays clear over time. It won’t be hurt by smells, water, or stains. This strong acrylic-cutting board is perfect for labs, kitchens, and other places where food is made. It also works well as a big acrylic-cutting board. It’s easy to clean and take care of. It lasts a long time.

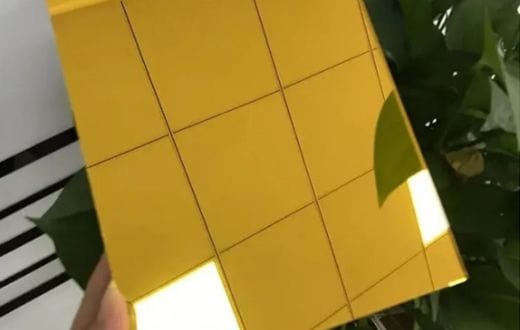

Customized Size Laser Cutting 3mm 5mm Pastel Cast Acrylic Sheet

You can get these Customized Size Laser sheets in soft pastel colors. They have a soft, modern look. A laser cuts the edges cleanly and neatly. You can meet different needs by changing the sizes. They would love decor items, crafts, and creative acrylic cut designs.

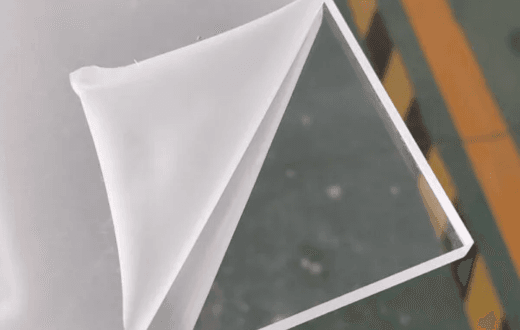

High Quality Laser Cutting Frosted Acrylic Laminate Sheet

This sheet has a smooth frosted surface. It looks great and is very neat. A soft and even light coming through. Laser cutting keeps edges clean and strong. It looks good in modern spaces like offices, dividers, panels, and the like.

Acrylic Cutting Board Templates Explained

An acrylic cutter board template makes it easy to make more than one of the same form. They become more accurate. Time spent making things is saved. They make fewer cuts and have less room for mistakes. You can use templates for both custom designs that you only need once and bulk orders. They help keep the same size and shape all the time.

Comparing the Cutting Methods

| Method | Edge Finish | Best Use |

| CNC Cutting | Smooth and strong | Thick sheets |

| Laser Cutting | Glossy and clean | Thin sheets |

| Hand Cutting | Simple finish | Small jobs |

Benefits of Professional Acrylic Cutting

- Smooth and safe edges

- Exact size and clean shape

- Less material waste

- Better visual appeal

- Longer product life

Professional acrylic cutting improves quality and value.

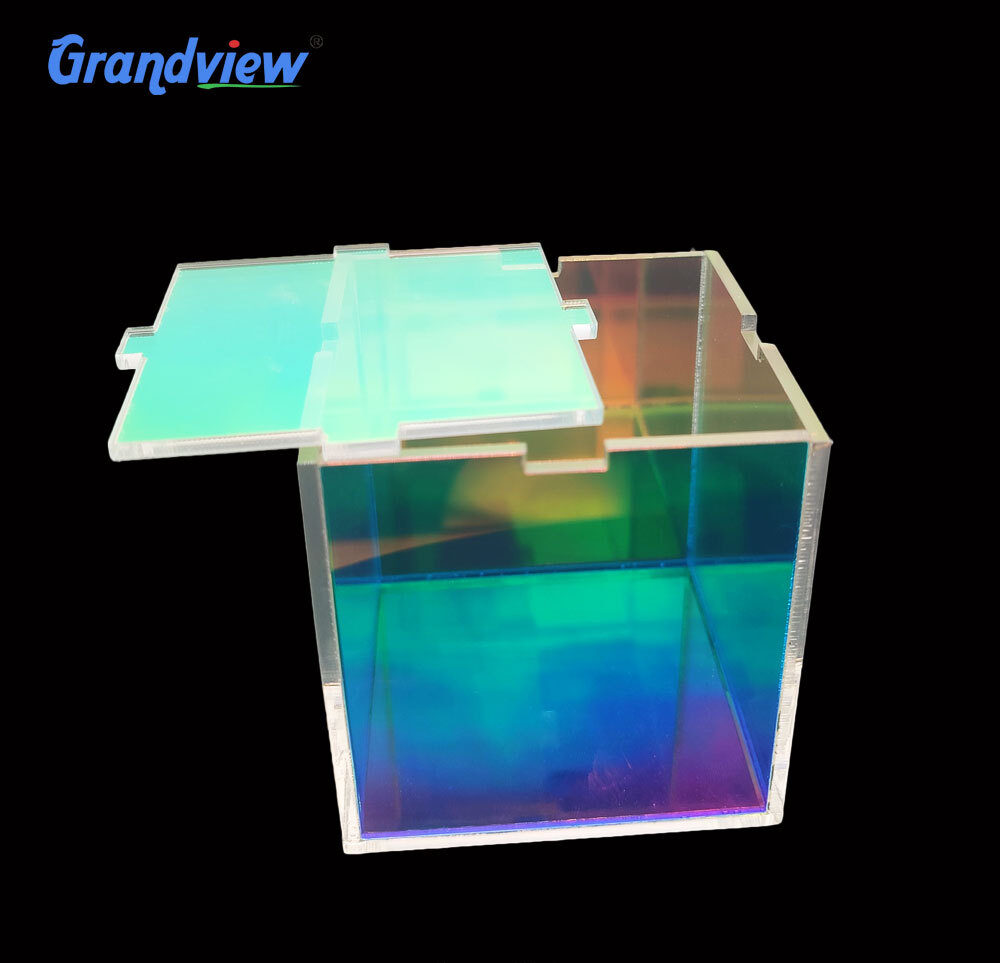

Grandview Acrylic is known for quality and trust. The company offers strong acrylic sheets and precise cutting services. Prices are reasonable. Product quality remains high. They support custom sizes and special designs. They use advanced machines and skilled workers. Clean edges and fine finishes are their primary focus.

Precision cutting improves acrylic quality. Clean edges make a big difference. Choose skilled cutting. Choose trusted experience.

FAQs

- What is the best method for acrylic cutting?

CNC and laser cutting are the best options. The choice depends on thickness and design needs.

- Can acrylic be used as a cutting board?

Yes. A custom acrylic-cutting board is strong, clear, and easy to clean.

- Is laser cutting safe for acrylic?

Yes. Professional machines carefully control heat and cutting speed.

- Where can I find a reliable acrylic-cutting company?

Grandview Acrylic is a trusted option for quality acrylic products and cutting services.