Manufacturing

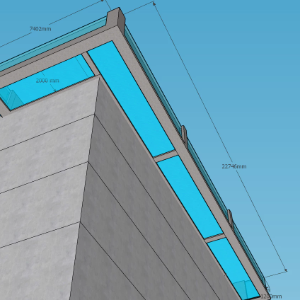

DESIGN & ENGINEERING

We make 3D design drawings for you, show you the viewing size, installation size and final projects. Through finite element analysis of force and stress, we recommend suitable material thickness for you

MONOLITHIC CASTING

We have 45 pools of various sizes, where the acrylic monomers are polymerized, we use MMA monomers from Lucite, and add anti-UV additives.

CNC MACHINING

Using a 5-axis CNC machine, we are able to make acrylic blocks in any shape you need. Ultra-fast processing capability makes our delivery time shorter and processing more precise

THERMOFORMING

We use steel molds to thermoform acrylic products with better precision than ordinary wood molds. We have 5 sets of ovens that can be temperature controlled

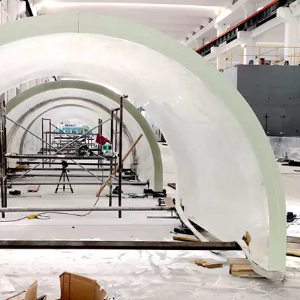

BONDING

We produce our own formulated glues using MMA monomers. Make the acrylic splicing tighter without air bubbles

ANNEALING

After the previous process is completed, we will anneal the acrylic product to relieve the stress of the material.=

POLISHING

Polishing is the final process, our workers will carefully polish every square centimeter of the product, making the acrylic more crystal clear

QUALITY CONTROL

Under the strong light, the workers carefully check each acrylic sheet to ensure that every product that leaves the factory is qualified

PACKING & SHIPPING

We use iron pallets and frames to protect your products from accidental damage during transportation and hoisting

INSTALLATION

We have a team of installation engineers, everyone has a passport, and can provide overseas installation services if necessary