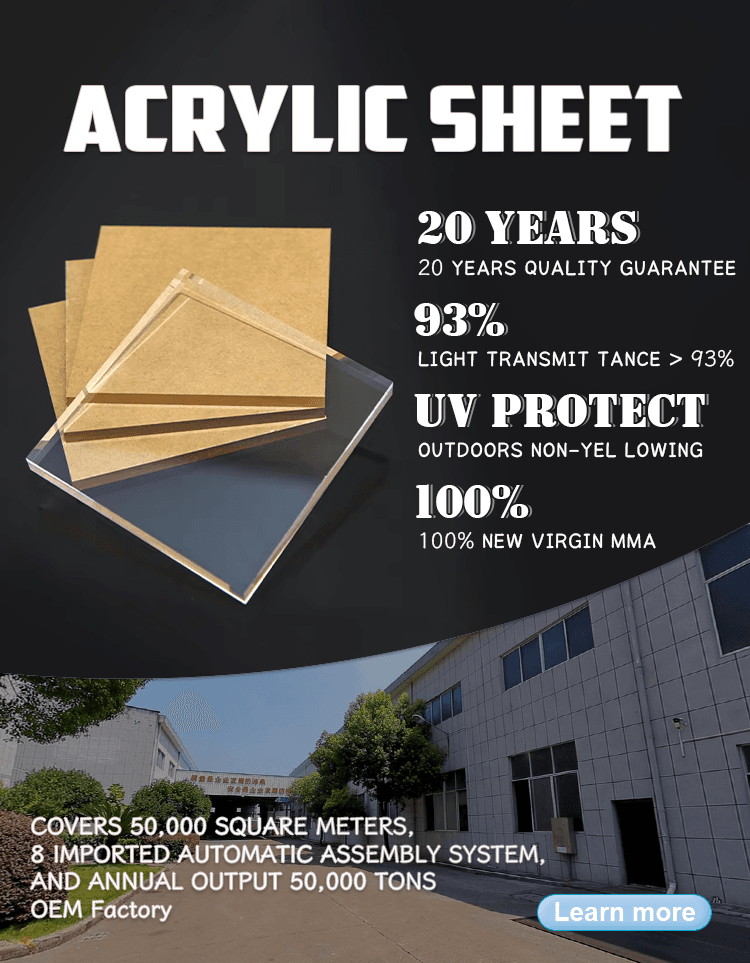

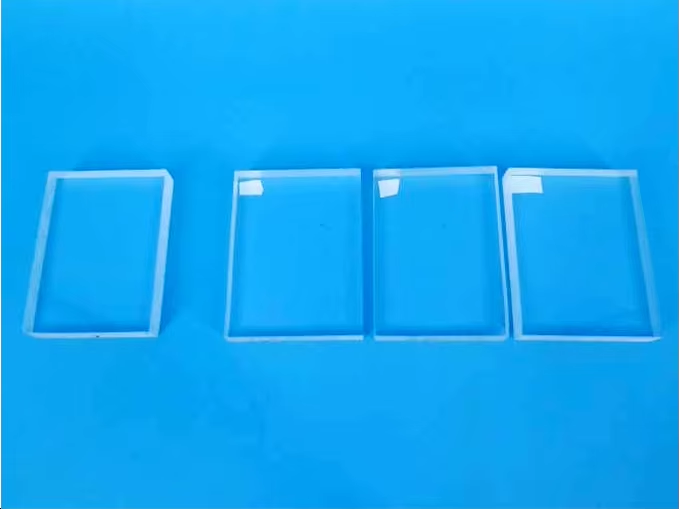

Experience industry-leading clarity and durability with our Grade A Cast Acrylic Sheets.

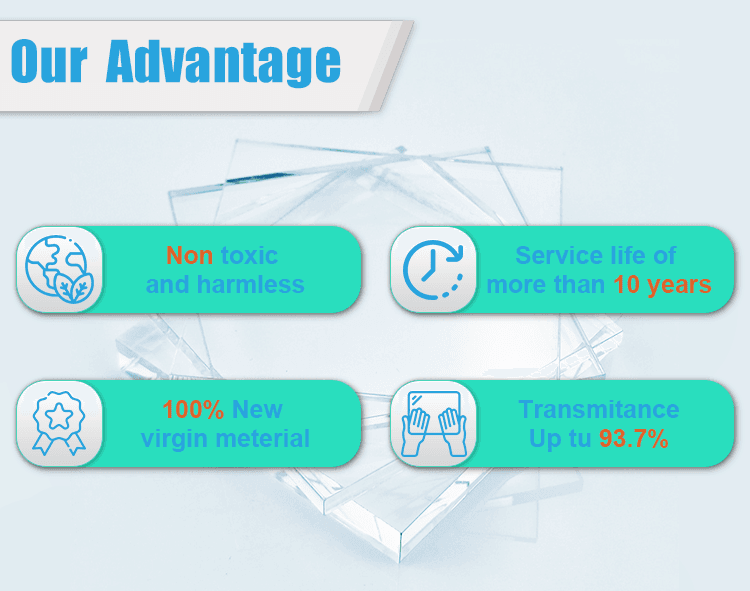

Warranty: 20 Years Quality Guarantee / 10 Years Non-yellowing.

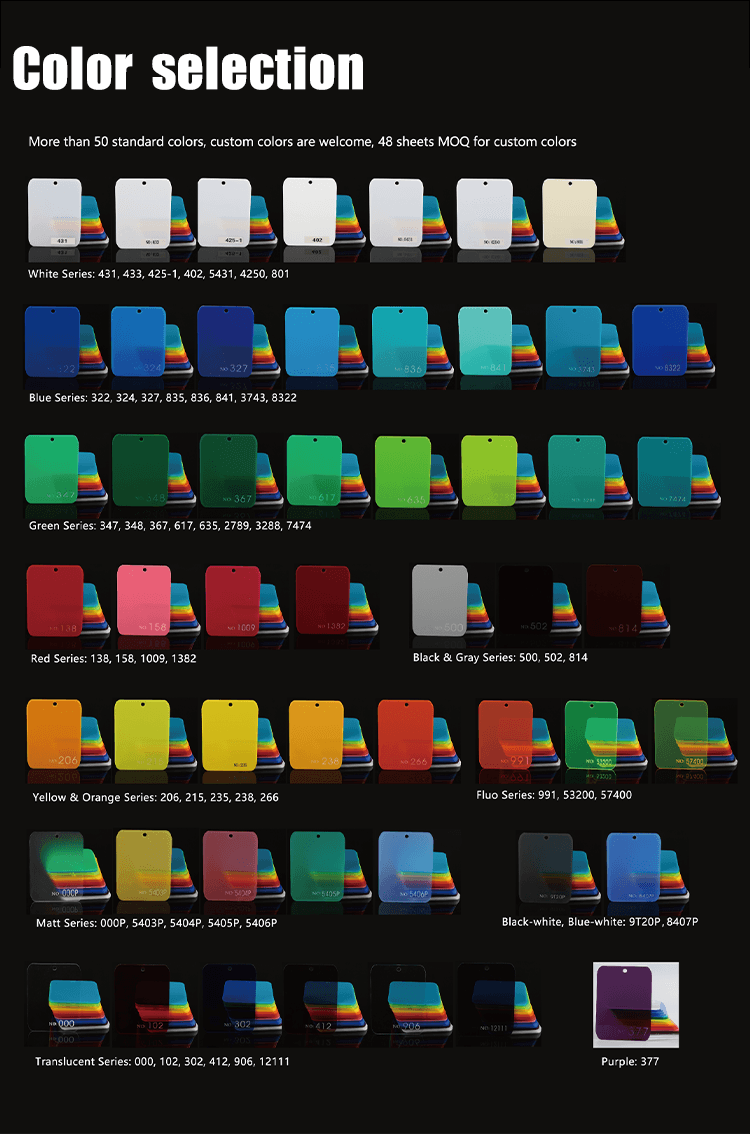

Material: 100% Virgin MMA (Lucite SH Factory).

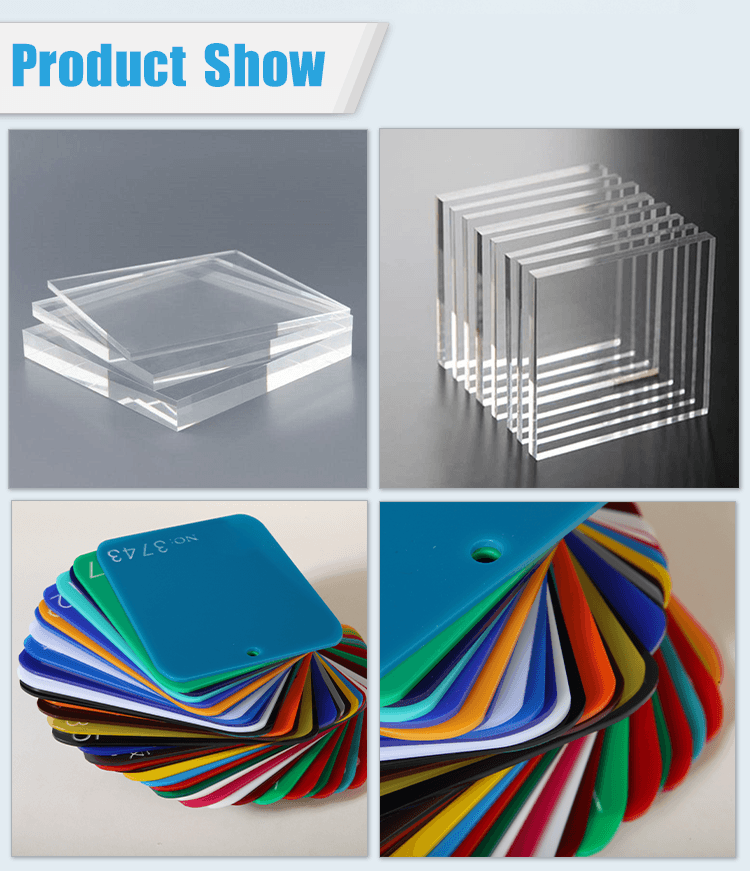

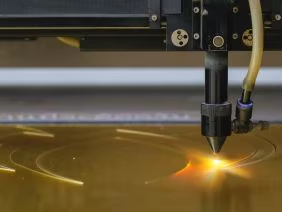

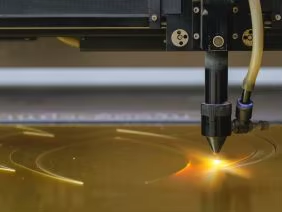

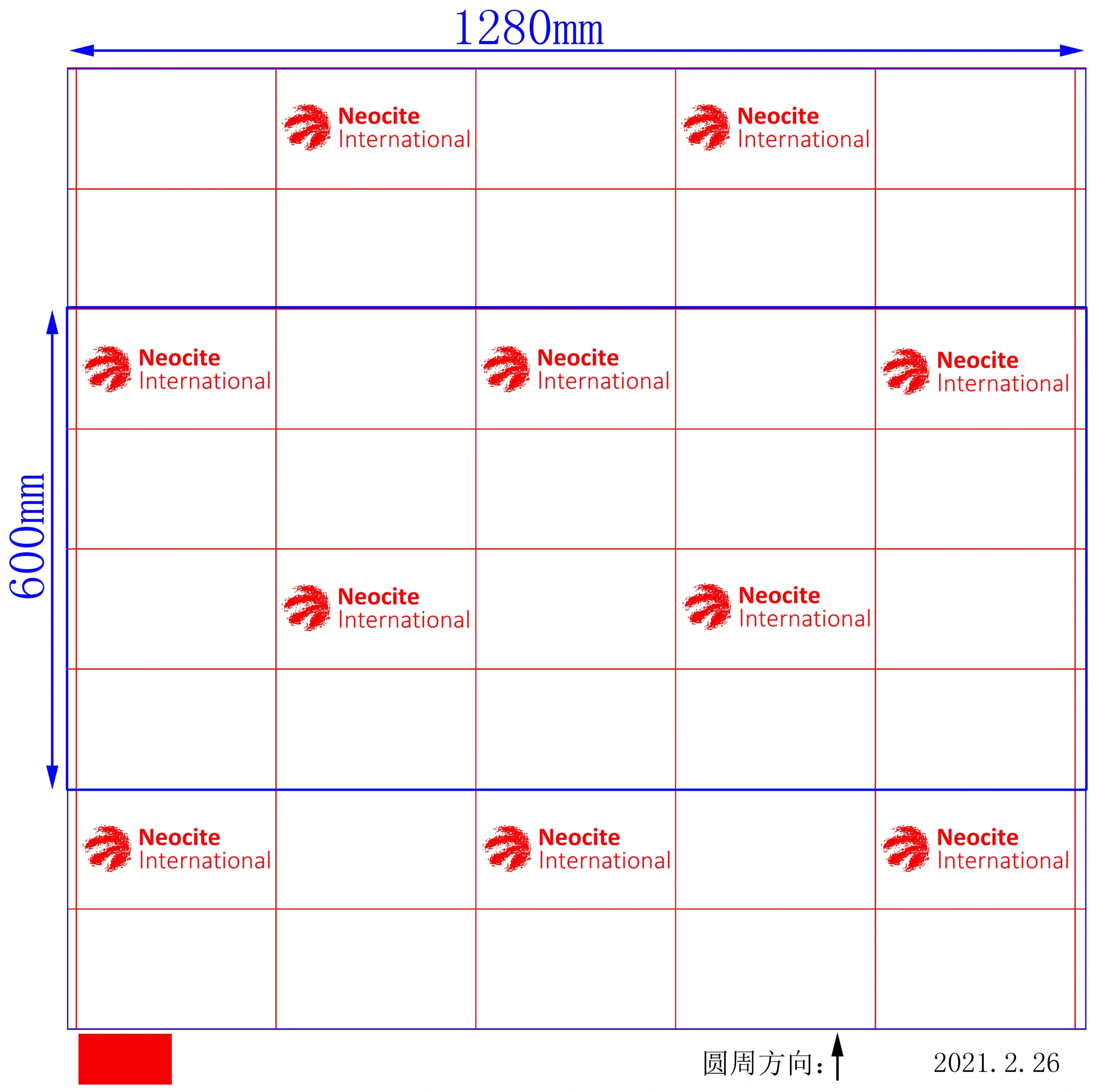

Customization: Precise CNC/Laser cutting and OEM logo printing available.

Performance: High impact strength and superior weather resistance.

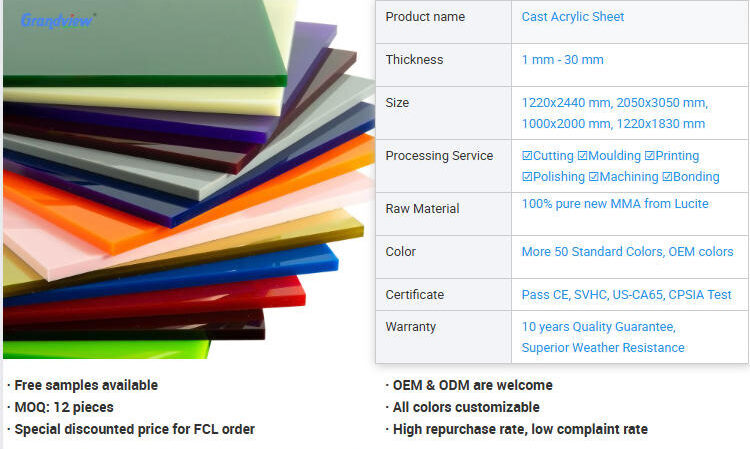

Product Detail

Acrylic Sheet Size & Thickness

Size ( mm ) | T ( mm ) | Size ( mm ) | T ( mm ) |

1220*2440 | 2-30 | 1500*3000 | 3-12 |

1220*1830 | 2-30 | 1500*2500 | 3-12 |

1000*2000 | 2-30 | 1600*2600 | 3-12 |

2000*3000 | 3-12 | 1780*2440 | 2-15 |

|  |  |  |

| Warranty | Pure MMA | CO2 Laser Cutting | Services |

| All acrylic sheets are UV resistant. Outdoor use warranty 8-10 years no yellowing no fading | A Grade Cast Acrylic Sheet with 100% pure all new MMA raw material from Lucite SH factory | CO2 Laser cutting No odor no smoke, easy to gule bond, easy to heat bending and forming | Provide additional CNC cut, CO2 laser cutting, printing, marking and other customized services |

|  |  |  |

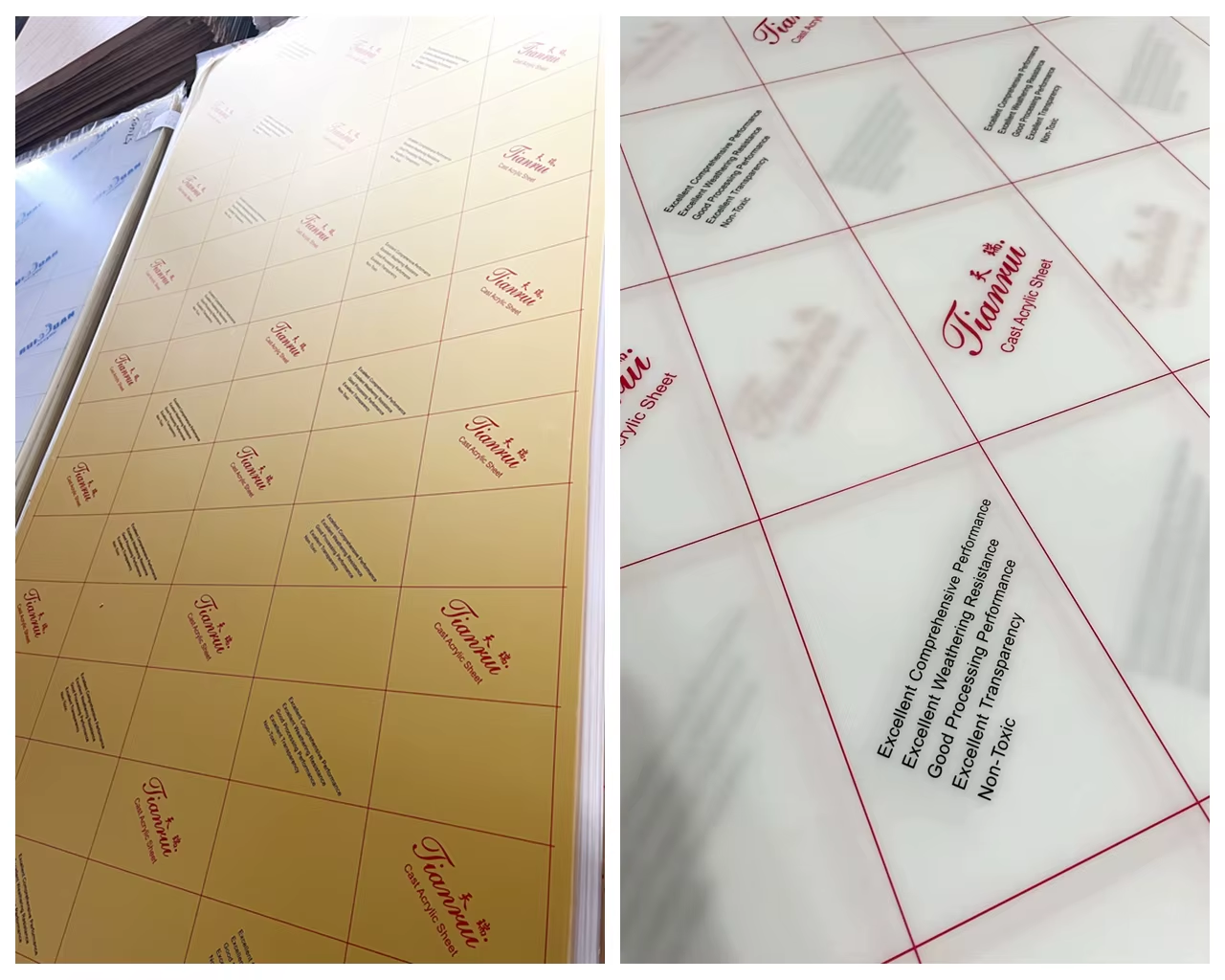

| Print Your Brand | Auto Production | Full Thickness | Proective Film |

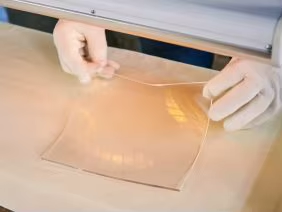

| You can print your own brand logo on protective paper and only need to pay a mold fee of US$600. | Advanced automated production line in the dust-free workshop | Sufficient thickness and best thickness tolerances | Protective film, reliable and durable, can be stacked, easy to move, no adhesive residue |

|  |  |  |

| Cementing | Cutting | Drilling & Routing | Edge Finishing |

|  |  |  |

| Laser Machining | Line Bending | Therm forming | Painting & Printing |

|  |  |  |

|  |  |  |

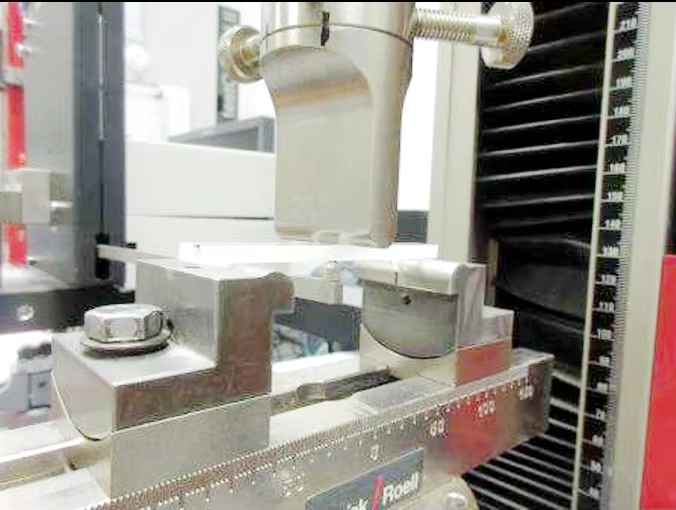

| Compressive Modulus – Stress – Strength | Flexural Strength | Izod Notched Impact Strength | UV Exposure Vicat Softening Temperature |

Rockwell Hardness | 112L | ISO 2039-2:1999 |

Tensile Modulus | 3150MPa | EN ISO 527:2012 |

Tensile Strength | 80.0MPa | EN ISO 527:2012 |

Tensile Strain at Break | 3.2% | EN ISO 527-1:2012 |

Water Absorption | 0.20% | ISO 62:2008 Method 1 |

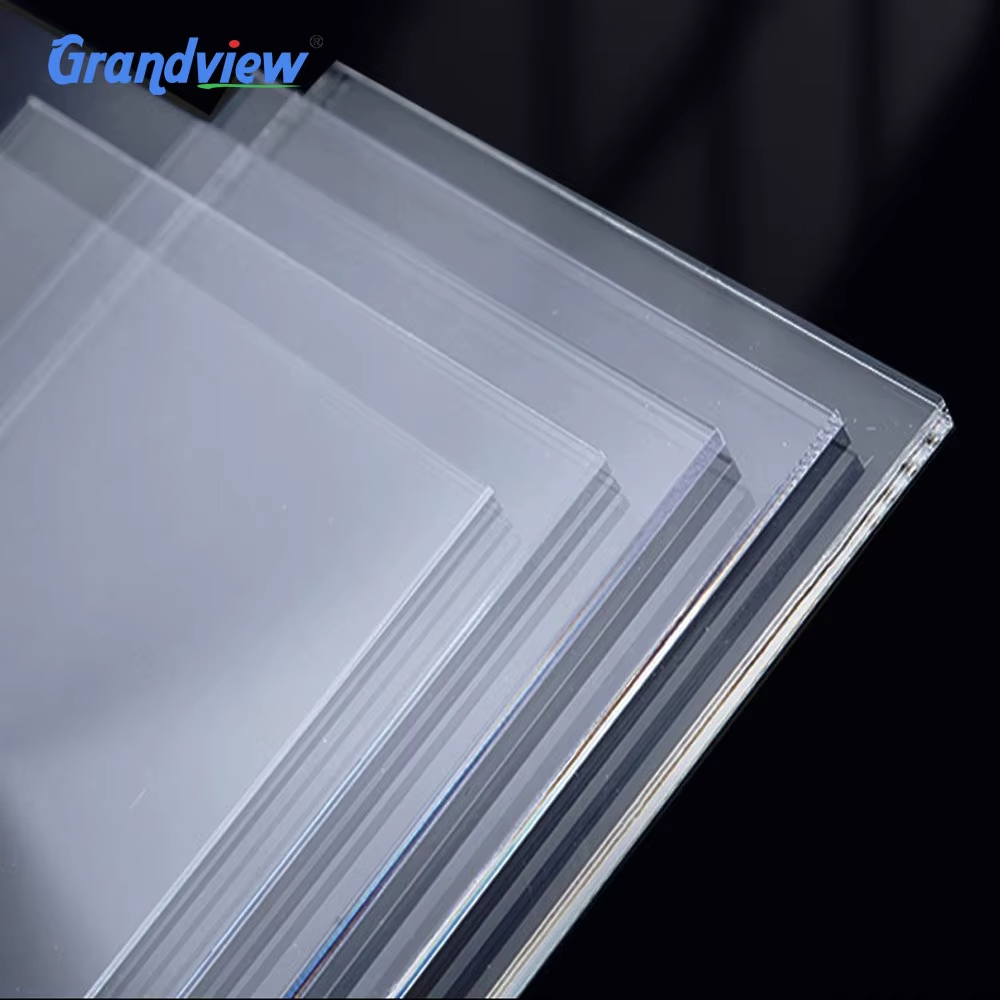

Total Luminous Transmittance | 92.5% | ISO 13468-1:1996 |

Vicat Softening Temperature | 103℃ | ISO 306:2013 Method B50 |

Light Ageing Test- UV Exposure | Grey scale: 5 | ISO 4892-3:2016 Cycle 1 |

Mean Coefficient of Linear Thermal Expansion | 72×10-6 K-1 | ISO 11359-1:2014 |

Compressive Stress at Yield | 129MPa | EN ISO 604:2003 |

Flexural Strength | 120MPa | ISO 178:2013 |

Izod Notched Impact Strength | 101J/m | ASTM D256-10 Method A |

Compressive Yield Strength | 111MPa | ASTM D695-15 |

Compressive Modulus | 3450MPa | ASTM D695-15 |

Shear Strength | 59.7MPa | ASTM D732-17 |

Deflection Temperature under Load | 100.2℃ | ASTM D648-18 Method B |

Outdoor anti-UV, the color change a little, non-yellowing or cloudy

Vicat Softening Temperature and Tensile strength Test each batch of Acrylic panels

All machined acrylic products is annealed to relieve stress

Superb bonding technology, so that the seams perfect

All new raw material MMA from Lucite factory local Shanghai

Strong Production Capacity, Huge stock, Fast delivery

Please give us a message for your enquiry, order or advice. Thanks a lot.