For the best durability and clarity in the aquarium acrylic manufacturing gets the most reliable manufacturer. With the premium quality aquarium acrylic you can always have the best outcome on your project. These acrylics are used for many sections. With the smart aquarium acrylic manufacturing process we provide you the exact detailed aquarium acrylics that last for a long time fit your needs exactly.

Why Choose Acrylic for Large Aquariums

Aquarium Acrylic is clear, light, and very strong. It is safer than glass and easy to shape into many styles. For large tanks or wide windows, it gives bright, smooth views that look almost like there is no wall at all. Many aquarium acrylic sheet manufacturers pick acrylic because it is strong, less likely to break, and has good optical clarity. Unlike glass, acrylic does not shatter into sharp pieces and is much lighter to lift and move. This makes it a top choice for public aquariums, zoos, hotels, malls, and even homes that want tanks as a main showpiece.

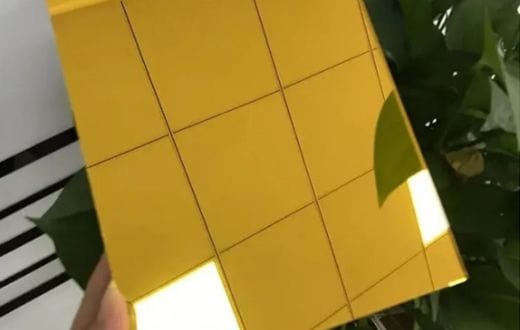

Premium Aquarium Acrylics With Luxury Designs

Acrylic Aqua Windows

Acrylic aqua windows are large, flat, and super clear. They let people see fish and plants in rich color and detail. These windows are seen in aquariums, parks, hotels, and even research labs. The optical clarity in aquarium acrylic windows makes sea life look sharp and bright. These panels can be made wide without breaks, making people feel closer to the water. The thickness requirements for large aquarium acrylic are always planned by skilled engineers, making sure panels are safe and strong. This makes aqua windows safe and amazing to see, letting visitors feel like they are part of the underwater world.

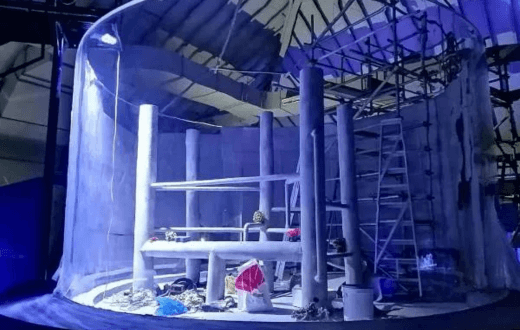

Acrylic Tunnel

An acrylic tunnel lets visitors walk under water while staying dry. It gives a complete view of sea life all around. It is one of the most loved features in large aquariums. How to bend aquarium acrylic panels is a key step here because the panels must curve without losing strength. With heat and thermoforming, the sheets are bent into smooth arches. Then, experts use seaming techniques in acrylic aquariums to join the panels. This makes the tunnel strong, leak-free, and long-lasting. Walking through a tunnel feels like diving into the ocean without getting wet.

Acrylic Cylinder

Acrylic cylinders are tall, round tanks that catch the eye. They are often placed in malls, hotels, and large halls. These tanks need strong seams, so experts use the best adhesives for aquarium acrylic joints to keep them safe. The round shape gives fish more space to swim in circles. Cylinders can be small for homes or very tall for public spaces. They are easy to polish and keep bright for years. This makes cylinders a favorite for private and public use where style and safety matter most.

Large Cube Acrylic Tank

Large cube tanks are modern, neat, and clear. They fit well in homes, museums, offices, and shops. The panels are thick and flat; workers join them with smooth seams. A complete acrylic aquarium panel polishing guide is followed to make them shiny and clean. This gives cube tanks a sharp and bright look. They can be made in many sizes and provide expansive, open views of fish. Families and businesses like them because they last long, look stylish, and easily keep clean.

Our Smart Aquarium Acrylic Manufacturing Processes

Design & Engineering

First our work starts with a plan made by engineers. They check the size, water load, and shape. After that we compare cast acrylic vs extruded acrylic for aquariums to pick the best type. Our designers work with customers to match looks, safety, and style.

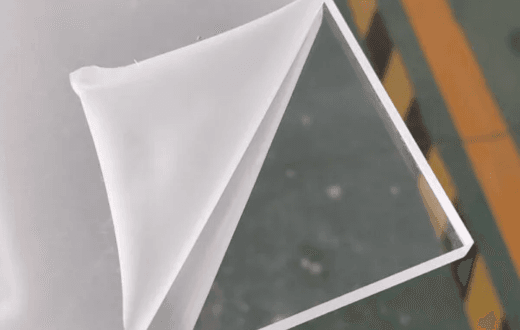

Monolithic Casting

The panels are made in strong molds and the casting makes sheets thicker and clearer. It helps hold high water pressure in large tanks. Casting also allows custom shapes and sizes.

CNC Machining

Machines cut sheets with sharp, fast tools, and the cuts are smooth and exact. Shapes for cubes, tunnels, and windows are made with ease, while CNC tools can also create intricate and special cuts with precision.

Thermoforming

In this process, heat makes sheets soft for bending. It is used to shape tunnels, domes, and round tanks. Bending aquarium acrylic panels is done with great care to maintain strength, and this step ensures the sheets stay strong and clear.

Bonding

The edges of panels are glued together using clear acrylic glue. The best adhesives for aquarium acrylic joints are chosen to make them safe. Experts join panels slowly to avoid bubbles, and this step ensures the tanks stay strong for many years.

Annealing

During annealing, heated sheets are cooled slowly and evenly. This process clears stress inside the sheet, stopping cracks and breaks. Panels that go through annealing last longer and are much safer.

Polishing

Panels are polished until they shine like glass. A complete acrylic aquarium panel polishing guide is followed. Scratches are carefully removed, edges are smoothed, and the tanks are made very clear and bright.

Quality Control

Every sheet is checked with great care. Clarity, edges, and seams are tested, and panels with any defects are not used. Only the best sheets pass the check for final use.

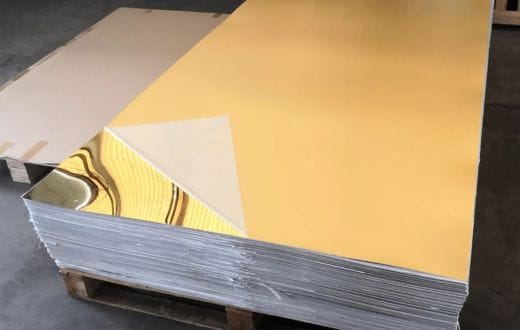

Packing & Shipping

Panels are packed in soft layers and placed in strong boxes. Corners are wrapped to stop chips and breaks. Factory cost acrylic aquariums are shipped worldwide, and careful packing keeps tanks safe on long trips.

Installation

Expert teams install the tanks at the site. Seams are tested for leaks, and tanks are checked for both strength and clarity. Only after passing these checks are they ready for public display.

Cast vs Extruded Acrylic for Aquariums

| Feature | Cast Acrylic | Extruded Acrylic |

| Clarity | Very high | Lower |

| Strength | Stronger | Weaker |

| Size | Very large | Limited sizes |

| Cost | More costly | Cheap |

| Stress Resistance | Resistance | Higher Lower |

| Life Span | Longer | Shorter |

Budget Aquarium Acrylic Project Ideas

There are many ideal and low-cost project ideas. Small cube tanks can be made for kids and homes, while tiny cylinders fit perfectly on desks or in cafes. Wall windows for shops and diners bring a unique touch, and mini tanks for classrooms help teach fish care. These projects are simple, budget-friendly, and enjoyable.

Top Supplier for Aquarium Acrylic Manufacturing

For top aquarium acrylic manufacturing visit Grandview Acrylic. We are trusted aquarium acrylic sheet manufacturers with many years of experience. We handle small and huge jobs with a smart aquarium acrylic manufacturing process. We are always making safe, strong, clear tanks for your needs.

FAQs

- Which is stronger, cast or extruded acrylic?

Cast acrylic is stronger and best for large tanks.

- Can acrylic bend without breaking?

With heat and care, it can bend into tunnels and curves.

- How thick should panels be for large tanks?

The thickness requirements for large aquarium acrylic change by tank size and water load.

- Can I build a budget acrylic tank?

You can use many budget aquarium acrylic project ideas to build safe and low-cost tanks.

- How are seams kept strong in large tanks?

For strong bonds, experts use clear glues and seaming techniques in acrylic aquariums.

- What is better for clarity, glass or acrylic?

Acrylic is more transparent, lighter, and safer than glass.